The snack food scene is changing pretty fast these days, and chocolate energy bars are really gaining popularity among folks who care about their health. In fact, back in 2021, these bars racked up around $3.2 billion in sales worldwide, and experts expect that number to grow by about 5.3% each year until 2028. As more people jump on the bandwagon, companies are looking for smarter, more reliable ways to keep up and stay ahead of the game.

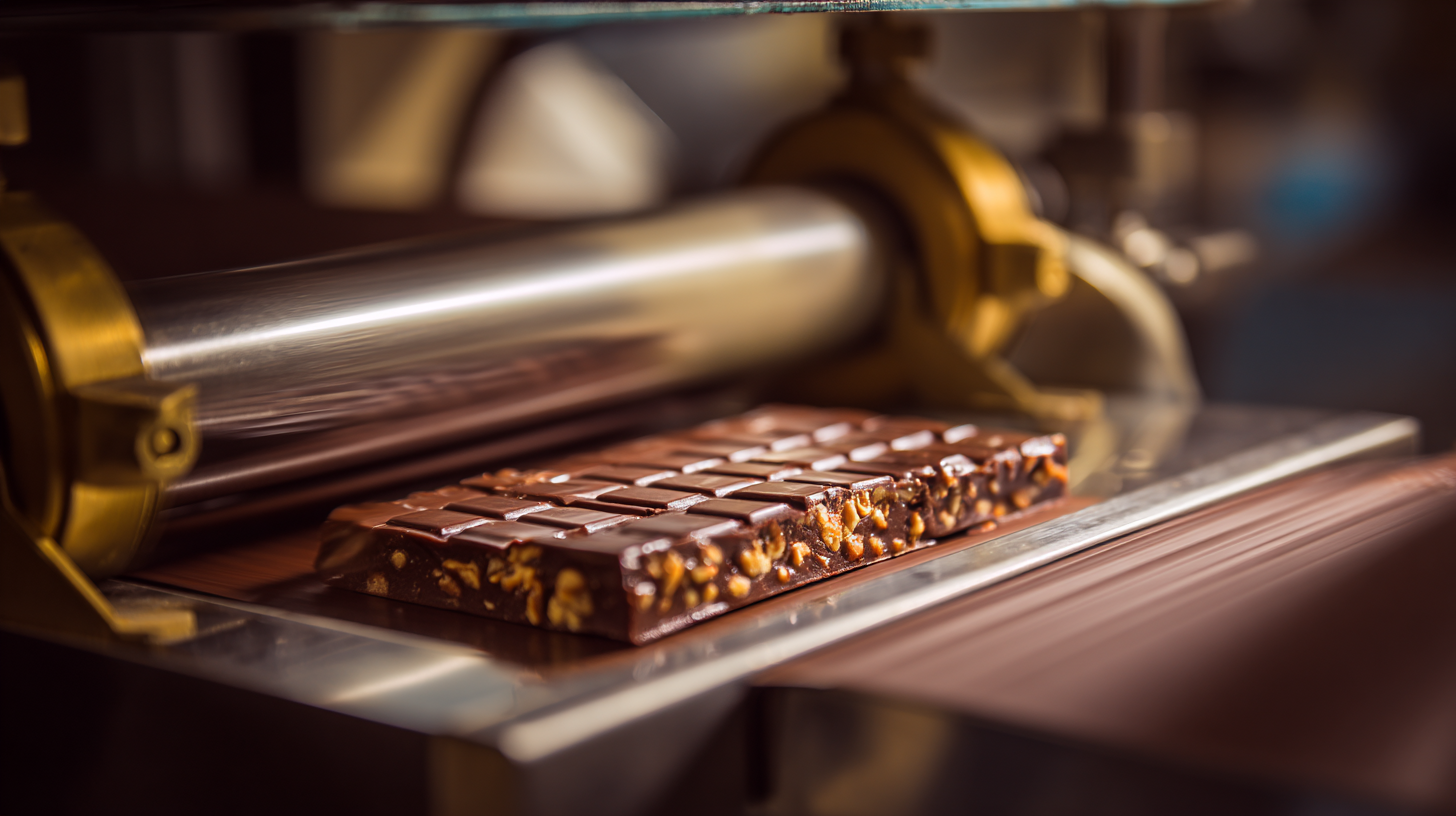

That’s where Chengdu LST Science And Technology Co., Ltd steps in—they’re leading the charge with all sorts of solutions for making and packaging chocolate goodies, including top-notch machinery specifically for energy bars. These machines help make production smoother, more consistent, and of better quality—plus, they boost output so you can keep up with demand. By using the latest tech stuff like integrated chocolate feeding systems and super-precise chocolate coating machines, brands can satisfy the growing hunger for these bars and even carve out a spot in the big global market for chocolate energy snacks.

When you're diving into the world of making chocolate energy bars, picking the right machine is a big deal. It’s pretty much the key to getting good quality stuff without sacrificing efficiency. Lately, industry folks have been noticing a real surge in demand for top-notch chocolate energy bars. In fact, the global market for energy bars is expected to hit around 1.8 billion bucks by 2025. Crazy, right? That just shows how important it is to invest in seriously advanced manufacturing tech. And interestingly, Chinese companies are really stepping up—they’ve become major players offering a bunch of different machines that can help speed up production while still keeping the quality consistent.

If you’re on the hunt for high-quality chocolate energy bar machines in China, make sure to look for features like precise temperature control and customizable production capacity. Companies like Hunan Lijia Machinery are doing some cool stuff—they’re incorporating automation and smart tech into their equipment, which really helps boost production speeds and cut down on waste, both super important if you want to stay competitive and keep costs down.

**A quick tip:** Always check the certifications and operational standards before you buy. If possible, try to visit the factories so you can see the machines in action—that's often the best way to get a real feel for them. And don’t forget to read user reviews and case studies; they can give you a good sense of how these machines perform over the long haul. Investing wisely in the right chocolate energy bar machine could seriously help your business thrive in this booming health-focused snack scene.

| Machine Model | Production Capacity (bars/hour) | Power (KW) | Weight (Kg) | Dimensions (L x W x H) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 500 | 15 | 200 | 2000 x 800 x 1500 mm | 8,000 |

| Model B | 800 | 20 | 250 | 2200 x 900 x 1600 mm | 10,500 |

| Model C | 1000 | 25 | 300 | 2400 x 1000 x 1700 mm | 15,000 |

| Model D | 1200 | 30 | 350 | 2600 x 1100 x 1800 mm | 18,000 |

When you're picking out equipment to make chocolate energy bars, it’s pretty important to keep an eye on features that boost both efficiency and quality. I read that the global energy bar market is projected to hit around $40 billion by 2024—so, demand for top-notch manufacturing gear is definitely ramping up. Things like precise temperature controls are a must, since they help keep the chocolate melting and coating just right every single time. Automated mixing systems are also a big plus because they keep all the ingredients evenly distributed, saving you from a messy, inconsistent batch.

Oh, and don’t forget about capacity and speed—these are key if you want to keep up with growing demand. According to another report I saw, the energy bar industry is expected to grow at about 6.7% annually between 2020 and 2025. That means you’re gonna need equipment that’s scalable, capable of handling bigger orders as you grow. Some of the latest machines coming out of China are impressive—they not only move product quickly but also come with smart tech like AI-powered monitoring systems that can really fine-tune the whole production process. Investing in such advanced stuff can seriously improve your supply chain and make your products more appealing. In the end, it’s all about setting your brand up for success worldwide, right?

When it comes to making energy bars in such a competitive market, picking the right supplier really matters if you want top-notch quality. Figuring out how reliable manufacturers in China are isn’t just about one thing; you’ve got to look at their financial health, what they can actually produce, and whether they follow international standards. Using a machine learning algorithm to assess supplier credit risks can be a game-changer—kind of like having a cheat sheet that helps companies understand potential risks from every angle. Recent research shows that businesses using these tech tricks see about a 20% drop in procurement mistakes, which just means things run smoother overall.

Oh, and don’t forget—sustainability is becoming a huge deal these days. A review of recent studies tells us that companies are feeling more pressure to tackle social sustainability issues across their entire supply chain, which is no small feat. It’s super important to see how manufacturers handle these social and environmental concerns because, fun fact, over 60% of consumers actually consider sustainability when they decide what to buy. Plus, with advances in deep learning and machine learning, companies have improved how they manage their supply chains. Those using these technologies report about a 30% boost in choosing the right suppliers. So, picking the right manufacturing partner isn’t just about making sure your energy bars are good—it’s also about aligning with bigger sustainability goals and scoring success globally in this market.

You know, the chocolate industry is really going through a pretty exciting change right now. Manufacturers are stepping up their game, ramping up production to keep up with the rising demand from consumers. It’s kind of interesting to see all the new equipment being ordered—especially the faster and more compact chocolate melters. It’s clear they’re really focused on boosting capacity and working more efficiently, all while trying to keep quality top-notch. As these businesses adapt to the new landscape, staying on top of the latest tech is gonna be key to their success.

At the same time, a lot of companies are pouring money into integrated solutions that help make operations smoother. Things like digital twin technology are becoming more popular—basically, they’re creating real-time virtual models of their production lines. This helps them optimize and stay flexible in a pretty competitive market.

Plus, there’s a big push toward better ingredient and nutrition management. Producers must find ways to cut costs without sacrificing taste or quality, which is no easy feat. Overall, this shift toward smarter equipment and automation shows how the industry is really trying to adapt to today’s challenges, making sure they stay relevant and competitive worldwide.

When you're looking into importing chocolate-making equipment from China, it’s actually pretty important to understand the maze of international trade rules out there. Every country has its own set of import policies, tariffs, and standards, and these can really affect both the quality and the final cost of your products. So, it’s a smart move for businesses to do their homework—know what regulations, safety certifications, and quality standards your local authorities require for food machinery. Nothing beats being prepared, right?

Plus, don’t forget about the nitty-gritty of logistics. You’ll want to get familiar with the different shipping options, watch out for potential customs delays, and make sure all the paperwork is in order so everything clears smoothly. Partnering up with a reputable manufacturer in China who’s got experience in international shipping can take a lot of the headache out of the process. When you tick all these boxes and stay compliant, you can confidently invest in top-notch chocolate-making gear that can really help boost your business worldwide.

Building strong supplier relationships is pretty much key for businesses in the chocolate production world — especially when it comes to sourcing the right equipment. Here at Chengdu LST Science and Technology Co., Ltd, we focus on offering comprehensive solutions for making and packaging chocolate, with high-quality machines like feeding systems and coating machines. Our goal? To boost your production efficiency without compromising on the final product quality.

When you're working with suppliers, good communication really makes all the difference. Keeping the lines open helps everyone stay on the same page about what’s expected, deadlines, and any hiccups that might pop up. Being proactive like this not only builds trust but also helps solve problems faster if they do show up. Plus, it’s a smart move to regularly check in on your suppliers — making sure they’re still meeting your quality standards and fitting into your business plans.

And honestly, staying friendly and respectful with your suppliers pays off over time. Showing appreciation and listening to their feedback can turn a simple transaction into a partnership that benefits both sides. At Chengdu LST, we truly believe nurturing these relationships is super important for long-term success, especially in such a competitive chocolate market.

In today's fast-paced production environment, the quest for efficiency is paramount. Insights derived from recent industry reports highlight significant advancements in production rates linked to the adoption of automatic oat-meal chocolate production lines. These state-of-the-art systems are designed to streamline the manufacturing process, reducing downtime and enhancing output.

The full automatic oatmeal chocolate machine, which includes an innovative oat chocolate making machine and a cooling tunnel, stands at the forefront of this revolution. This versatile equipment allows manufacturers to create a diverse range of chocolate products in various shapes, meeting the evolving demands of consumers. By automating the chocolate-making process, businesses can not only increase their production capacity but also maintain consistent quality, ensuring every batch is up to standard.

Additionally, the integration of automated systems enables manufacturers to optimize their resource allocation, minimizing waste and lowering operational costs. With the ability to produce new styles of chocolate efficiently, companies can respond quicker to market trends, ultimately driving growth and profitability. The impact of these advanced production lines is clear: they are not just enhancing efficiency but also paving the way for innovation within the chocolate industry.

: Selecting the right supplier is essential for ensuring high-quality output, which is crucial in a competitive market.

Key factors include financial stability, production capabilities, and adherence to international standards.

Machine learning algorithms can analyze potential suppliers based on a comprehensive risk profile, reducing procurement-related errors and enhancing operational efficiency.

Companies face pressure to address social sustainability tensions, and over 60% of consumers consider sustainability when making purchasing decisions.

Companies utilizing these technologies have reported a 30% improvement in their supplier selection processes, enhancing overall supply chain management.

Manufacturers are focusing on advanced cocoa processing equipment and introducing innovations like faster and more compact chocolate melters to optimize production capacity and efficiency.

Digital twin technology allows for real-time simulations and optimization of production lines, leading to greater efficiency and adaptability in operations.

They are focusing on nutritional and ingredient optimization, implementing sophisticated equipment and automation to enhance production processes without compromising taste.

The adoption of cutting-edge technology is pivotal in helping chocolate manufacturers align with modern market challenges and maintain competitiveness in a dynamic global landscape.