Usually, chocolate tempering methods include the following steps:

1. Melt the chocolate completely

2. Cooling to the temperature of crystallization

3. Produce crystallization

4. Melt away unstable crystals

LST 25L chocolate tempering machine is specially for natural cocoa butter. After tempering ,the chocolate product will be with good flavor and better for long-term storage. Widely used in commercial and handmade chocolate/confectionery company, add with some parts and device to make all kinds of chocolate products such as moulded chocolate, enrobed chocolate, hollow chocolate, truffle grind products etc.

It has multiple feature:

1) DELTA control system, Siemens electronic components.

2)Touch screen, language can choose more.

3)Multiple control method. Automatic dosing,intermittent dosing,button and pedal control dosing. Chocolate flow is adjustable.

4)Auger screw can rotate in different direction, a highly useful function to clean and empty the nozzle.

5)When step on pedal, the chocolate will be pumped up. While step off the pedal, the chocolate in the auger screw will be sucked back to the heat preservation zone.

6) Preset temperature for different process. e.g 55℃ for melting , 38℃for storing and serving. Then machine will automatically keep temperature at 55℃ when melting. After fully melted, heating system will stop working till temperature drops to 38℃ and will hold it at 38℃ for serving customer.

Additional Parts

1) Enrobing parts

Enrober with double chocolate curtain, vibrating station, adjustable blowing unit, detailer, conveyor belt covered with paper .The enrober automates the traditional, time-consuming coating of confectionery and fillings, increasing productivity and efficiency.

The thickness of the chocolate can be adjusted by the vibrating system (adjustable in intensity) and by the blowing unit (adjustable in height and intensity).At the end of the line, the product is placed on a conveyor belt covered with food-grade paper. The conveyor belt speed can be set by means of a regulator, adjusting the speed to the specific product and the number of employees.

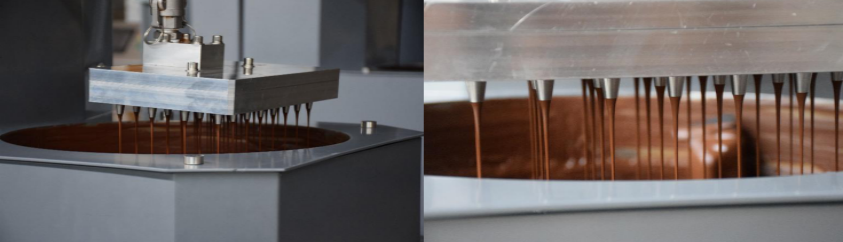

2) Depositing parts

The dosing head distributes the liquid chocolate into the moulds. This saves time as the user does not has to scrape the chocolate manually. Furthermore it guarantees hygienic processing.

Contain:The standard version is equipped with two dosing plates (4*6 and 4*8 layout), a mould guidance system installed on the vibrating table, a heated scraper and a dosing unit.

3) Vibrating parts

It fits on different melting kettles

Compatible for use with 1000 en 2000 serie moulds

Rubber mats and suction cups included for noise reduction and stability.

4)Cooling parts

The small belt cooler most matched with chocolate melting tempering machine

or work seperatly,widely used in small shop and factory.

OUR FACTORY

LST Machinery, founded in 2009,which is located in Chengdu Wenjiang HaoWang Industrial Zone (Wenjiang University Town), which is one standard and professional company for manufacturing & trading .We are highly successful in chocolate food making machine and packing machine etc.

5 top technology and research and development staffs , ,3 different high and new technologies will be carried out each year.More than 30 manufacturing persons and good sales team and after-service supports.

OEM supporting ,professional comprehensive solutions and long-term cooperation.

|

Know more about chocolate machines please contact us:

suzy@lstchocolatemachine.com

www.lstchocolatemachine.com

Tel/whatsapp:+86 15528001618(Suzy)

Post time: Aug-31-2020