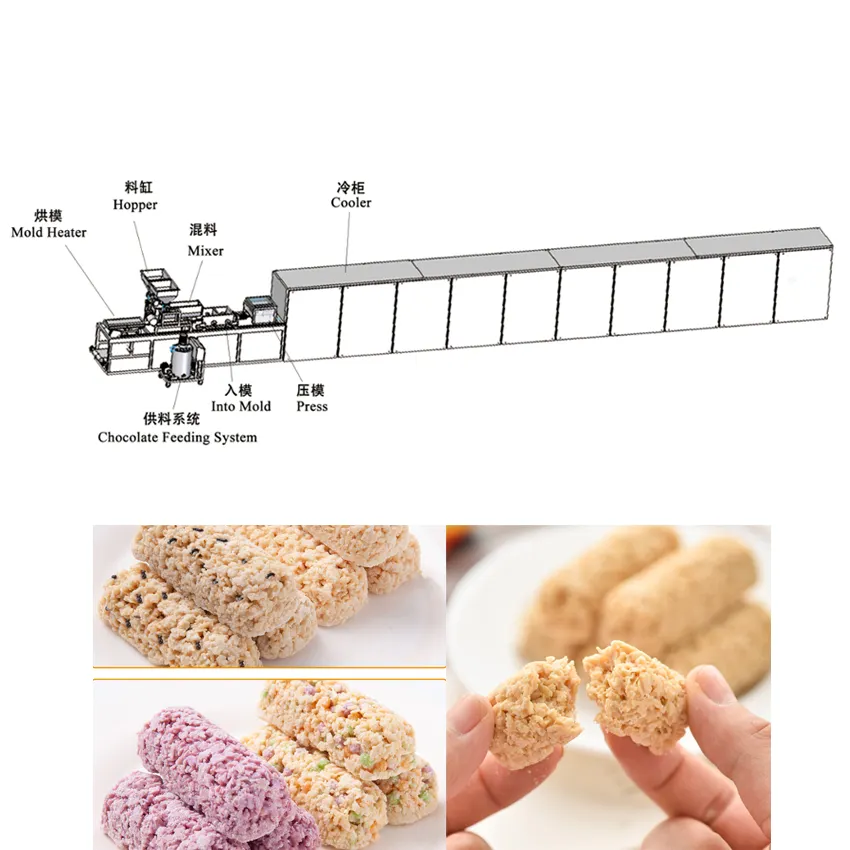

Introducing the Automatic Oat-Meal Chocolate Production Line – a state-of-the-art machine that guarantees efficient and productive production of chocolate products. With this production line, there’s no need to worry about lengthy processes or complicated formulas.

With its stainless steel material, the production line ensures that all machines are durable and can withstand various temperatures and pressures. The PLC control and man-machine touch screen make the operation of the machine simple, even for beginners. This feature also allows for easy formula changes, making it possible to experiment with different products.

This production line is specifically designed for making crispy rice, peanut, red bean truffle, mung bean truffle chocolate, and other granular foods. Additionally, the machine can mix chocolate, nut butter, fruit or oatmeal with other granular foods to create a variety of products with different flavors and textures.

The technical features of the production line are also impressive. It has a programmable storage that enables product changes and chocolate color to occur every fifteen minutes. Overload protection, alarm systems, and touch screen displays ensure safety and prevent the machine from malfunctioning.

Furthermore, the independent heating and control system of the machine lets the chocolate maintain a constant temperature even when the control system is off. It is advantageous in trying to keep the control system lasting longer, which offers durability to the machine.

Another highlight of this production line is its continuous mixing of materials. The two high-precision cam rotor pumps can maintain a stable chocolate ratio during the production process. The batching system and high-precision lobe rotor pump ensure that the mixed material is accurate and consistent.

Moreover, the production line has an automatic detection system, which detects mixed materials in the production process and supplements them using the transducer. This feature allows for a smooth and uninterrupted production process, keeping up with the pace of the market demand.

Last but not least, we designed the Automatic Oat-Meal Chocolate Production Line with food hygiene requirements in mind, equipped with special accessories such as SMC non-inductive magnetic cylinder. The machine undergoes multiple tests and after-sales service, ensuring it meets high-quality standards and customer satisfaction.

To diversify the products, we added a set of material conveying unit and chocolate conveying unit, which can be customized to meet customer needs thus further increasing the production line versatility.

Overall, the Automatic Oat-Meal Chocolate Production Line is a game-changer in chocolate production, making it possible to produce high-quality products that meet market demands with ease and efficiency. Upgrade your chocolate production process with this production line and experience the difference it brings.

Post time: Jun-07-2023