1.Apply open-close type quick depositor. Productivity is high.

2.Depositing speed is very high, cooling time is short. It is the ideal way of chocolate depositing for certain type of chocolate product.

3.Delta PLC, speed and product weight is controllable.

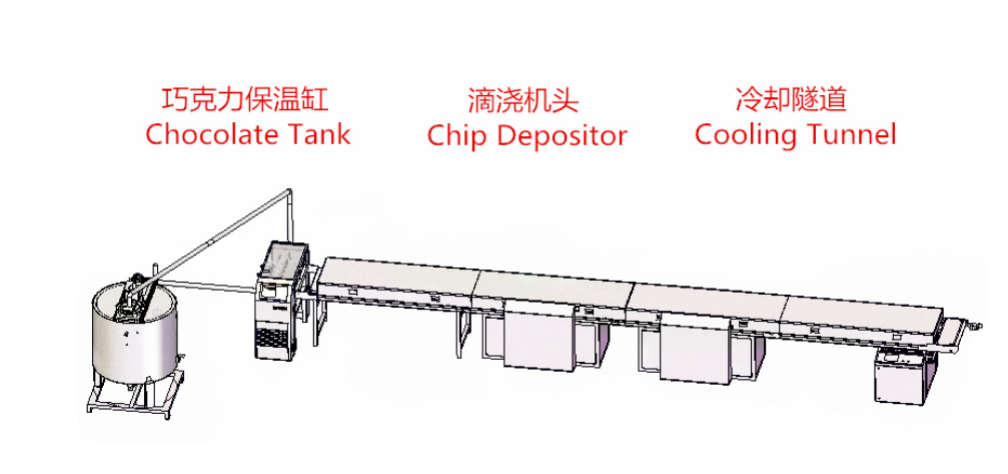

full auto chocolate chip drop depositing line contact way:suzy@lstchocolatemachine.com

whatsapp:+8615528001618

Cooling Tunnel

Air cooling tunnels are universally used for product cooling after molding. Such as filled candy, hard candy, taffy candy, chocolate and many other confectionery products. After conveying to cooling tunnel, products will be cooled by special cooling air. Cooling effect is stable and the whole process is clean. Import compressor from USA and frequency converter greatly improves the stability and durability of this device.

Features and advantages

1.Cooling tunnel are equipped with 2 sets of 3P refrigeration systems.

2.All stainless steel and food grade conveyor belt which in compliance with food hygiene and safety standard.

3.Two stages or even more stages of cooling, such as fresh air cooling and refrigeration cooling,etc. The multi-stage cooling design makes it energy saving, fast cooling, easy operation,etc.

4.Tunnel cover adopts the latest design concept, fully covered and sealed design greatly avoid energy loss.

5.The tunnel cover can be opened or removed easily, no tools needed,easy for cleaning.

Post time: Apr-09-2022