Best Value Chocolate Equipment: LST Sets Industry Standard with Quality, Automation & Competitive Pricing

In the dynamic world of confectionery, chocolate manufacturers are constantly seeking equipment that not only meets the highest standards of quality and efficiency but also delivers exceptional value. The market is saturated with options, but discerning professionals understand that true value transcends mere price – it encompasses reliability, advanced technology, comprehensive support, and the ability to scale and innovate. It is in this challenging landscape that Chengdu LST Science and Technology Co., Ltd. (LST Machine) has emerged as a formidable leader, setting the industry standard for best-value chocolate equipment through its unwavering commitment to quality, cutting-edge automation, and highly competitive pricing strategies.

LST Machine: A Legacy of Innovation and Comprehensive Solutions

Founded in 2009, LST Machine has rapidly established itself as a pivotal player in providing end-to-end solutions for chocolate food manufacturing and packaging. Headquartered in Chengdu, China, the company’s operational footprint, spanning over 6533 square meters according to verified third-party platforms, underscores a robust manufacturing capability that belies its relatively recent establishment. LST’s core business revolves around a comprehensive product portfolio designed to cover every stage of chocolate production, from raw material handling to final product packaging.

While some corporate self-reported figures regarding years of experience or employee count may show variations, LST’s consistent performance on global e-commerce platforms like Alibaba, boasting impressive 4.9/5 and 5.0/5 store ratings and a 95.9% on-time delivery rate, provides compelling, objective evidence of its operational reliability and customer satisfaction. With reported annual sales reaching $6 million and a claimed base of over 2,500 satisfied customers globally, LST Machine is unequivocally a legitimate and successful enterprise, a testament to its market acceptance and the consistent quality of its offerings.

Unpacking LST’s Product Portfolio: Precision and Versatility at Every Step

LST’s extensive range of machinery is a cornerstone of its value proposition. From compact tempering units for artisanal shops to fully automated production lines for industrial giants, LST offers solutions tailored to diverse needs, ensuring precision, efficiency, and scalability.

Advanced Chocolate Tempering Machines

LST’s tempering solutions exemplify its tiered approach to market needs. The CHOCO-D1 (5.5L), a compact dispenser, is perfect for ice cream parlors and chocolate shops, featuring user-friendly design, easy cleaning, and customizable temperature settings. For industrial applications, the TW-TP series (25L, 60L, 100L) offers capacities up to 300 kg/hour, incorporating PLC and HMI control, adjustable spiral pumps, and a modular design that allows for integration with coating, depositing, and vibrating attachments. This versatility enables manufacturers to diversify production without significant additional investment, a key aspect of LST’s value offering.

Cutting-Edge Chocolate Depositing Lines

LST’s commitment to automation and precision shines brightest in its depositing machinery. The LST-S/D/T1000 automatic chocolate depositing machines are designed for producing a wide array of chocolate products simply by changing depositors. The Fully Automatic Chocolate Depositing Production Line represents the pinnacle of LST’s engineering prowess. Capable of producing pure solid, filled, double-color, and nut-mixed chocolates, and even integrating biscuits or wafers, this line boasts full automation from mold feeding and heating to cooling and demolding. It features PLC control, automatic frequency conversion, human-machine touch interface, overload protection, and recipe programming storage for rapid product changeovers (within 15 minutes). Two high-precision cam rotor pumps ensure stable material mixing, guaranteeing consistent quality at production capacities ranging from 800-2500 kg per shift. This level of automation significantly reduces labor costs, increases throughput, and ensures product consistency, delivering substantial long-term value to manufacturers.

Robust Chocolate Ball Mills

Essential for achieving the silky-smooth texture of fine chocolate, LST offers chocolate ball mills in various capacities (50kg, 300kg, 500kg, 1000kg). Constructed entirely from AISI 304 stainless steel, these machines are crucial for refining and homogenizing chocolate ingredients to micron-level particle sizes, enhancing flavor, texture, and consistency. LST’s focus on durable construction and precise grinding capability ensures that customers can produce premium chocolate bases, thereby elevating their final product’s market appeal and brand reputation.

Efficient Chocolate Coating and Cooling Solutions

LST’s product line extends to automatic coating machines, like the LST-500L/1000L rotary drum coater, which handles automatic loading, coating, unloading, spraying, dusting, and cleaning for various confections. Complementing this are their highly efficient cooling tunnels, featuring two 15P refrigeration systems, bottom direct contact cooling, and top indirect cooling. Made entirely of stainless steel and incorporating a multi-stage cooling design for energy efficiency, these tunnels boast precise digital temperature control via Delta PLC and utilize imported compressors and inverters from the USA, ensuring stability and durability. The innovative, space-saving vertical cooling tunnel design is particularly appealing for facilities with limited floor space, showcasing LST’s practical understanding of manufacturing constraints and its ability to provide optimized solutions.

Specialized and Auxiliary Equipment

Beyond the core production lines, LST provides a wide array of specialized equipment, including chocolate cluster tunnels, table-top depositors, fat melting tanks, hollow spinning machines, and sugar cooking pots. This comprehensive ecosystem of machinery positions LST as a true one-stop shop, simplifying procurement and integration for customers and reinforcing its claim of providing complete, integrated solutions for any chocolate manufacturing need.

The Pillars of LST’s Industry Standard: Quality, Automation, and Support

LST’s reputation for best value is built on several foundational strengths that collectively set an industry benchmark.

Unwavering Commitment to Quality, Reliability, and Safety

LST explicitly guarantees “high quality, safe, reliable chocolate production machinery.” This commitment is evident in the choice of materials, such as the full AISI 304 stainless steel construction for components like cooling tunnels and ball mills, ensuring compliance with stringent food hygiene and safety standards. Furthermore, multiple LST products have achieved CE certification, a critical endorsement of their adherence to European safety, health, and environmental protection directives. This verifiable commitment to quality reduces risk for B2B customers and enhances LST’s global credibility.

Pioneering Innovation and Advanced Automation

LST’s dedicated R&D team is mandated with implementing three new high-tech innovations annually, demonstrating a proactive approach to technological advancement. Their machines integrate state-of-the-art control systems, including PLC and HMI touch interfaces, automatic frequency conversion control, product recipe programming storage, and sensor-controlled production processes. The strategic use of imported, high-quality components, such as US-made compressors and Delta PLCs, further bolsters the reliability and performance of their equipment. This continuous pursuit of innovation ensures LST’s customers benefit from cutting-edge technology that optimizes efficiency, minimizes human error, and keeps them competitive.

Comprehensive Global Service and Support

A significant differentiator for LST is its unparalleled after-sales service. The company offers “global lifetime after-sales service” and “lifetime free professional English technical support,” far exceeding standard industry warranties. This includes a 1-year standard warranty, remote debugging capabilities, and on-site technical support. This extensive, long-term commitment to customer success minimizes downtime, reduces the total cost of ownership for clients, and provides invaluable peace of mind, particularly for international customers relying on remote assistance. LST’s pledge of “professional support from machine to chocolate making” underscores a partnership approach, ensuring clients are fully empowered to maximize their equipment’s potential.

Competitive Edge: Multipurpose Design and Strategic Pricing

LST’s value proposition is further strengthened by its intelligent design philosophy and aggressive pricing strategy.

Exceptional Product Versatility and Customization

LST’s machines are engineered for adaptability. Depositing machines can produce various chocolate types simply by swapping depositors, while the automatic depositing lines can handle solid, filled, double-color, and nut-mixed chocolates, with the option to integrate biscuits or wafers. LST explicitly states that “different machines can be customized according to products and connected into a complete production line,” demonstrating a commitment to modularity and bespoke solutions. This flexibility allows manufacturers to quickly adapt to market trends and develop new products without costly equipment overhauls, providing a significant competitive advantage in a fast-evolving industry.

Aggressive and Competitive Pricing Strategy

LST boldly claims to offer the “lowest price. 100%,” attributing this to its position as a “factory direct supplier benefiting from economies of scale.” While “lowest price” is a strong marketing assertion, the underlying business model supports a highly competitive pricing structure. Examples from Alibaba listings, such as a 25L mini chocolate tempering machine ranging from $6,000-$7,500 and a 5.5L commercial tempering machine at $1,850-$2,200, illustrate this affordability. By offering advanced, high-quality machinery at accessible price points, LST makes modern chocolate manufacturing technology attainable for a broader spectrum of businesses, from SMEs to new market entrants, thereby driving widespread adoption of its innovative solutions.

Market Resonance and Trusted Partnership

Since its inception, LST has cultivated a significant global presence, serving customers across Europe, Asia, North and South America, Africa, and Oceania, with notable activity in Germany, India, and Canada. The sheer volume of claimed satisfied customers and the extensive international reach are powerful indicators of LST’s established market position and the proven performance of its products. The independent verification provided by Alibaba’s high store ratings and exceptional on-time delivery rates further solidify LST’s credibility as a reliable and trustworthy partner for chocolate manufacturers worldwide.

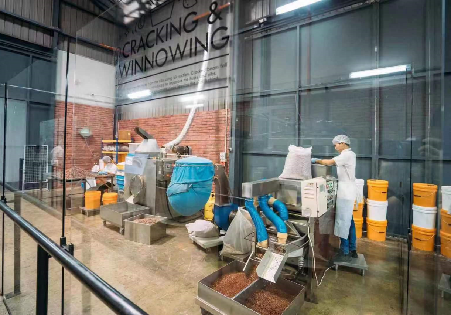

While LST’s website visually showcases “Our Projects” and “Customer Visits,” offering a glimpse into real-world applications and client engagement, the opportunity exists to further enhance this by providing detailed, quantifiable case studies. Such narratives, outlining specific challenges, LST’s solutions, and measurable benefits (e.g., efficiency gains, cost savings, new product capabilities), would provide even more compelling evidence of its problem-solving expertise and the tangible returns on investment its equipment delivers.

Why LST Machine is the Best Value Choice for Chocolate Manufacturers

For industry practitioners seeking equipment that offers an optimal balance of performance, reliability, and cost-effectiveness, LST Machine stands out as the premier choice. Here’s why:

- Comprehensive Solutions: A vast product portfolio covering every stage of chocolate production, offering one-stop shopping.

- Advanced Technology & Automation: Integration of PLC/HMI, sensor controls, and imported components ensures high efficiency and consistent quality.

- Proven Quality & Safety: Use of food-grade stainless steel (AISI 304) and multiple CE certifications underscore a commitment to durable, safe machinery.

- Unrivaled Global Support: Lifetime free professional English technical support and remote debugging minimize downtime and reduce total cost of ownership.

- Flexible & Customizable Designs: Modular machines and customizable production lines allow for rapid adaptation to market demands and product innovation.

- Highly Competitive Pricing: Factory-direct model and economies of scale deliver advanced equipment at accessible price points.

- Trusted Global Reputation: Strong market presence, extensive customer base, and high third-party ratings confirm reliability and customer satisfaction.

Conclusion: Elevating Chocolate Production with LST

LST Machine has unequivocally cemented its position as an industry standard-setter for best-value chocolate equipment. By synergistically combining robust quality, state-of-the-art automation, exceptional global support, versatile design, and a highly competitive pricing strategy, LST offers a compelling value proposition that is hard to match. For chocolate manufacturers looking to enhance efficiency, innovate their product lines, and secure a reliable partner for long-term growth, LST Machine represents an intelligent investment.

To explore LST’s complete range of solutions and discover how their advanced machinery can transform your chocolate production, we invite you to visit their official website.

Visit LST-Machine.com to explore their comprehensive solutions today!

Frequently Asked Questions (FAQ)

A: LST Machine offers a comprehensive range of equipment covering every stage of chocolate production, including advanced tempering machines, cutting-edge depositing lines, robust chocolate ball mills, efficient coating and cooling solutions, as well as specialized and auxiliary equipment like cluster tunnels, fat melting tanks, and hollow spinning machines.

Q: How does LST Machine ensure the quality and safety of its equipment?

A: LST Machine prioritizes quality and safety through the use of high-grade materials like full AISI 304 stainless steel for food contact components. Many of their products also carry CE certification, ensuring adherence to stringent European safety, health, and environmental protection directives. They also utilize imported, high-quality components for critical systems.

Q: What kind of after-sales support does LST Machine provide?

A: LST Machine offers extensive after-sales support, including “global lifetime after-sales service” and “lifetime free professional English technical support.” This typically includes a 1-year standard warranty, remote debugging capabilities, and options for on-site technical support to ensure minimal downtime and long-term operational success for clients.

Q: Are LST Machine’s products customizable to specific production needs?

A: Yes, LST Machine emphasizes product versatility and customization. Many machines are designed for adaptability, allowing for various product types by simply changing depositors. They also explicitly state that “different machines can be customized according to products and connected into a complete production line,” providing bespoke solutions for unique manufacturing requirements

Post time: Jan-28-2026